New Technology Solutions

OnionCam, and the TechNature Lineup

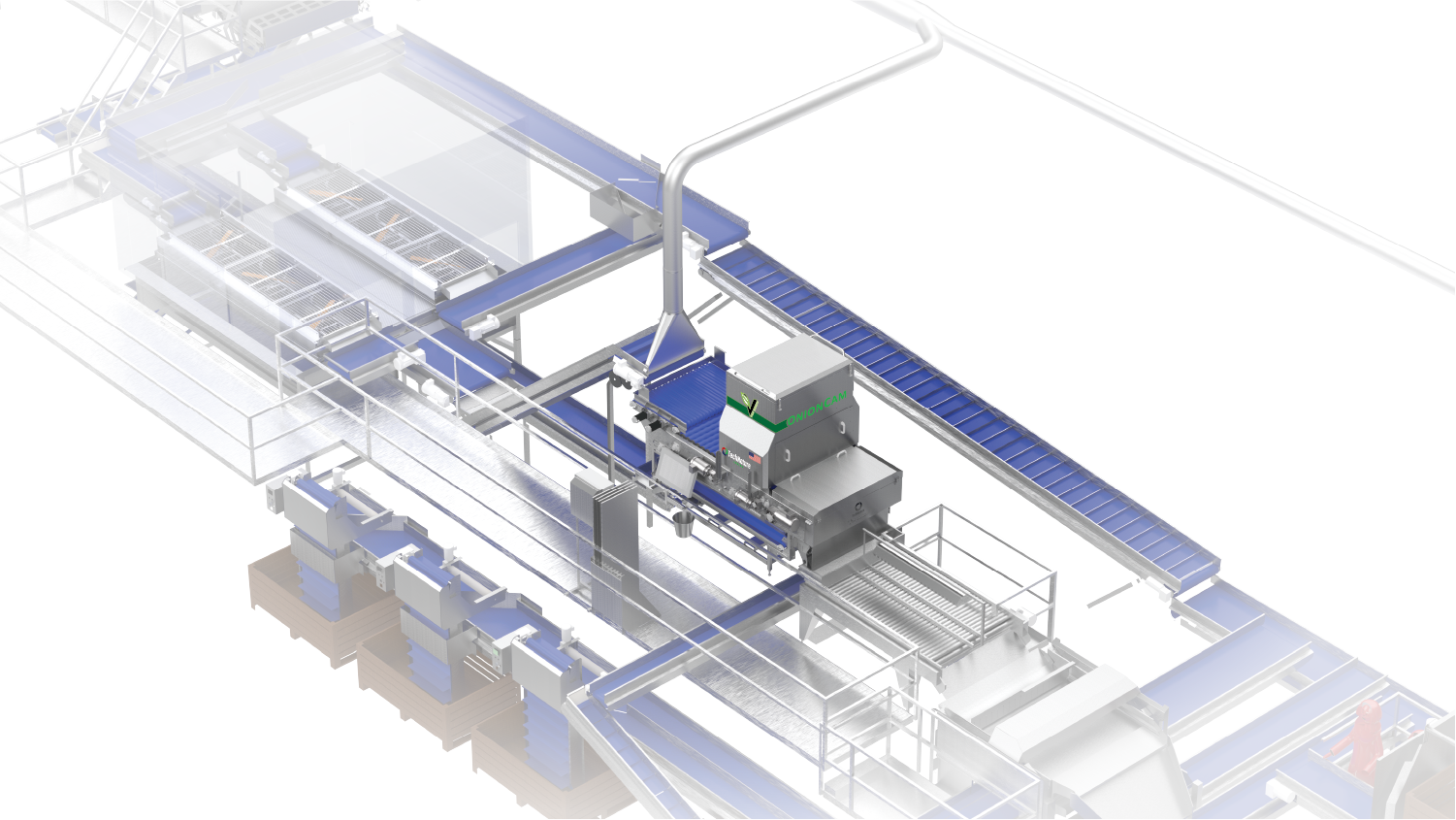

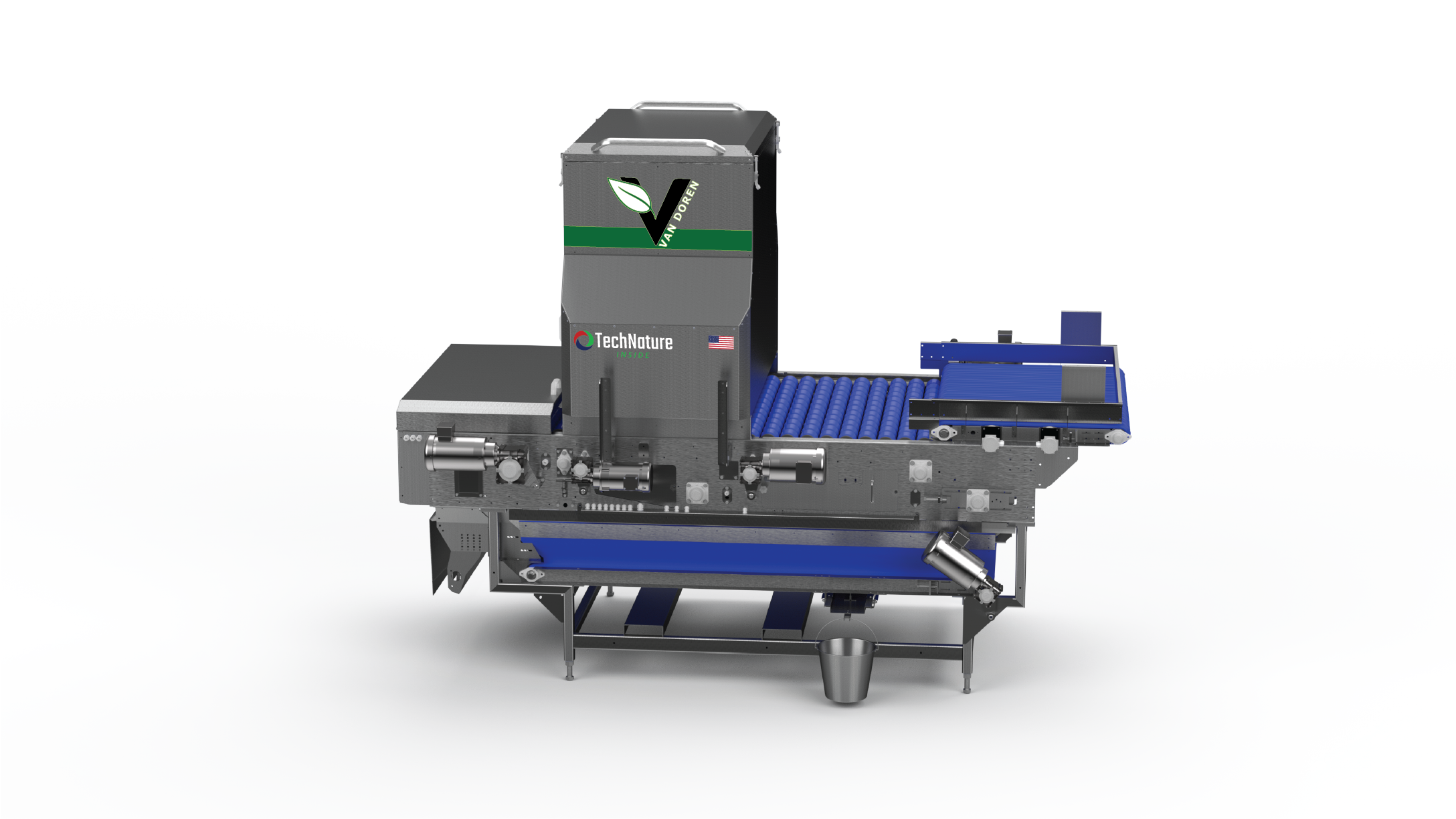

Van Doren has entered into a strategic technology partnership with TechNature to bring some of the world’s most advanced grading systems to the onion packing and processing industries. TechNature's imaging system employs multiple camera angles and produce rotation to capture comprehensive views of each piece of produce. The accuracy of this grading system reduces the need for manual sorting, creating a rapid return on technology investment. This system’s unique sorting process allows multi-grade sortation and can be integrated seamlessly into most existing packhouses.

Designed for Produce Care

The OnionCam system utilizes a flat belt and diabolo rollers to ensure gentle transitions into singulated lanes for imaging and grading. Handling rates of 15 to 30 tons per hour* requires careful produce care, which is achieved through the scalloped design of the diabolo rollers. These rollers optimize lane filling, ensuring smooth singulation into the grading section. The diabolo rollers gently cup the produce, maintaining singulation during imaging for superior handling across the sizer platform. Equipped with roller rotation, they provide complete modeling under the imaging cabinet, resulting in exceptional grading accuracy.

Enhanced Views of Produce and Intuitive HMI

Van Doren and TechNature are producing OnionCam with eight side-view cameras and four top-view cameras to gather produce images. The rotational diabolo rollers section of the machine ensure total product rotation while imaging for complete modeling of produce. The HMI (Human-Machine Interface) or touchscreen controller features a simple grading criteria screen to set a profile for identifying defects. From the main control page, easy-to-use sliders give operators the power to adjust the severity of the grading criteria to improve grading results. From the analysis screen of the program users are equipped with a tool to quickly adjust these produce grades and test how manipulation will affect the results of grading before applying them to the performance of the grader.

Built for Quality and Longevity

Van Doren and TechNature are committed to designs focused on durability and food safety. Both companies commitment to hygienic equipment pushed design engineers to prioritize the use of food safe materials in the construction of the machinery. Our design focuses on the longevity of the equipment, ensuring a durable and long-term grading solution for our customers. This commitment to quality and sustainability underscores our dedication to providing reliable and efficient grading systems that stand the test of time.

Previous New Technology Features

Case Optimization Robot [COR]

COR was developed in partnership with our global integration partner GlobalPac to complete the automated tray filling solution with Aporo the robotic tray filling solution, and Van Doren’s Vertical Carton Conveyor to create a tray filling solution that can be integrated into existing packing operations.

The new platform has been developed with a Right-hand and Left-hand counterpart for better integration directly into existing tray filling solutions.

Integrated Case Handling

Automated Tray Placement

Vacuum Powered Pick-and-Place

Integrated Tray Centering

Packs up to 8 Trays/Min

Apple SLS Bagging Solution

This Apple Bagging System was developed by Van Doren Sales using the TOMRA SLS Platform as a way to manage weight and size management going directly into bags. Through the sizer’s imaging and weight acquisition, bags of produce have precise weights, in addition to a very high throughput!

Integrated apple Transportation

Integrated Bag Transportation

Batching of apples for precise weights

Integrated bagging and clipping system

Able to add bagging outlets based on length of sizer

TerraGrade Cable Sizer for High Volume Sorting

This cable sizer platform was designed for high throughput and gentle produce handling. The unique shaker and v-belt singulation system minimizes the transfer height into the equipment, and the diverging belt transfer ensures a gentle and secure transfer onto cable sizer lanes. Through this robust design, the v-belts system reduces overflow onto cables, minimizing the recycle rate for the sizer. This system boasts 5 tons/hour per lane of sizer for russet potatoes, and is available from 2-12 lanes on a single sizer frame. Additionally, the pneumatic kickers were designed for consistency and speed. Consistent pneumatic pressure, a low-profile design, and a rapid cycle rate ensure delivery to grading outlets. Through Van Doren’s installation, a full integrated data suite can be integrated into the system to give operators and controllers full insight and control over the system with performance displays and robust reporting. TerraGrade is a sizer platform that has several options available for optical grading and Artificial Intelligence (Ai) sorting systems, complete with controls and integrated communications.

Stainless steel construction with food grade produce contact surfaces

Open-top design for ease of access and sanitization of equipment

Low-profile high speed pneumatic kickers

Diverging V-Belt singulation system for increased capacity

Minimized produce drop heights

Compatible with several options for optical inspection and Ai Grading systems